Technical Details

Textile reinforcement

Our products get their superior strength and form stability from using high-performance polyester textiles. For special applications we can also use textiles based on other materials, such as fibers made of aramid, glass, basalt or steel. We apply both knitted and woven textiles depending on the intended use of the finished product.

Weight

Weight is used as an indicator of the robustness of the fabric. Many customers use weight per square meter as an indicator of both durability and strength. However, strength and durability are affected by other factors too, such as the structure of the textile, amount of applied PVC and subsequent surface treatment. It is therefore important to check several parameters before making a choice of what quality should be used.

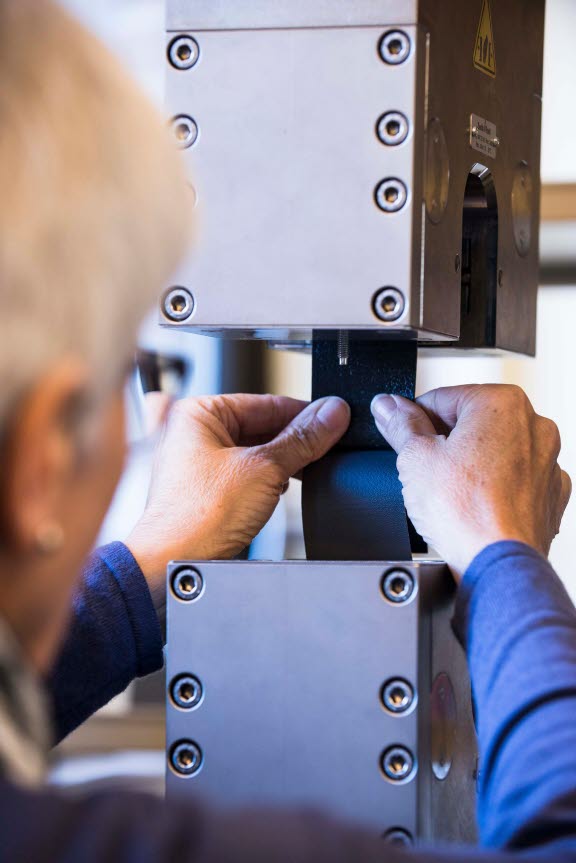

Tensile strength

The tensile strength of a fabric is the maximum tensile force it can resist before it breaks. We declare the tensile strength in both the warp (longitudinal) and weft (transverse) directions of the textile.

The unit of the tensile strength is N/50 mm, i.e. the strength of a test specimen of 50 mm width.

If the tensile strength is 4000 N/50 mm, and the design load for the construction is 400 N/50 mm, then the factor of safety is 4000 / 400 = 10.

Elongation

When a fabric is exposed to a load, it deforms by stretching (it becomes longer). This phenomenon is called elongation (or tensile strain).

Elastic elongation is the elongation you can reach without permanently deforming your sample (e.g. elongations up to 2 % is typically elastic). That is, how much can you stretch it, and still have the sample snap back to its original length once you release the stress on it. The elongation is measured in percentage of the original length. The total elongation at maximum force is typically in the range 15-25%.

The product of tensile strength and total elongation at maximum force constitutes the ‘fracture toughness’ of the membrane. A material with high strength and high elongation is very robust.

Tear Strength

The tear strength of a fabric tells us how much force we must use to tear it apart. We declare the tear strength in both the warp (longitudinal) and weft (transverse) directions of the textile.

The unit of the tear strength is N.

As with tensile strength and elongation, tear strength can help you determine the durability and lifespan of the fabric, but this characteristic will give you a better impression on how the material holds up after damage has already been sustained.

Adhesion

Adhesion characterises the delamination strength between the PVC coating and the textile reinforcement.

The unit of the adhesion is N/50 mm.

Adhesion will give you an understanding about the strength of welded joints. It will also give you an indication of the durability of the material under cyclic loading conditions.

Finish

Colour

Technical textiles from Protan is offered in a range of standard colours, depending on the quality/area of use. For the most used all-round PVC coated fabrics, special colours can be ordered from our colour catalogue.

No Lacquer

No lacquer is standard finish for all our products. The exposed surfaces are made of plasticised PVC.

Topcoat - lacquer

A PVC fabric finished with a topcoat will provide a premium quality surface without altering the welding properties. Protan uses two kinds of lacquer as topcoat:

PVDF lacquer (Polyvinylidene fluoride) provides superior protection against wear and tear, weathering, and chemical protection to the membranes when necessary. PVDF lacquer is recommended when durability is of the essence and/or the product will be exposed to harsh environments or conditions.

Acrylic lacquer also provides a high-quality topcoat, and this topcoat can be used for applications that are less exposed to demanding environments. Both our lacquer qualities work well for all common joining technologies, i.e. high frequency welding and hot air/hot shoe welding.

Topcoat | 1-sided PVDF lacquer

1-side PVDF lacquer is suited for applications where only one side will be exposed to demanding conditions.

Topcoat | 2-sided PVDF lacquer

2-sided PVDF lacquering will secure protection on both sides of the product when high robustness is required. Two-side lacquering can also be used when end-user processes demand flexibility on which fabric side that points inwards or outwards, respectively

Topcoat | PVDF + Acrylic lacquer

Products with 1-side PVDF lacquering and 1-side acrylic lacquering, combine extra protection in an optimized, robust, and more cost competitive fabric.

Properties

Blackout

For blackout membranes we add light blocking agents into the fabric, and this prevent light transmittance through the membranes.

Blackout membranes are used on all applications where light and bright environment are not desired. This can thus prevent unwanted plant growth, protect equipment/people from sunlight or enforce light discipline for tactical advantage.

UV / UV+

Our standard products are UV resistant, but for demanding applications – additional protection can be provided.

UV+ products have extra UV stabilising packages added to the formulations, especially intended for highly exposed materials in sunny areas.

Fire Resistance | Fire Retardant

Our fabrics comply with a range of fire classifications. Common to all fire classes is a certain ‘resistance to fire’. However, there are also requirements on ‘resistance to smoke generation’ and ‘resistance to generating flaming droplets’.

Different applications require different standards and levels of requirements, and our products comply with a range of ‘resistance to fire’ standards, including EN-, DIN-, FAR- and IMO standards.

Other standards can also be accommodated, but that requires specific testing and certification.

Vapour resistant fabrics

Special temporary buildings require special requirements for protecting the construction against water vapour ingress. Lacquered products provide a highly resistant barrier against water vapour transmission.

Watertight

Protan membranes form an effective waterproofing barrier and are extremely versatile in terms of application opportunities. The flexibility of our fabrics represents possibilities where only the imagination sets limits. Examples of applications can be water basins, underground constructions, pools, ponds, septic tanks, manure bins, artificially buried fountains, etc.

Chemical resistance

PVC coated fabrics have very good chemical resistance in a wide range of environments. However, for cases where our products are continuously exposed to liquids, vapours or gases from industrial or agricultural operations, please contact us for further advice.

Protan also provides PVC/PUR coated textiles with even greater chemical resistance, and for special applications these qualities should be applied.

Potable water grade

These are membranes for containment of potable water (e.g. water reservoirs or tanks). The membranes can also be used for floating covers or floating baffles. Protan potable water grade PVC fabrics are anti-seepage, waterproof, UV resistant, and have long service life.

Anti-Slip

Protan 900 Anti-slip is an anti-slip fabric well suited for flooring in temporary structures such as fabric halls for storage, industry, sports, retail, etc. Also used in structures prone to spills, such as field hospitals.

The embossed surface provides a non-slippery surface for particular applications.

Dimensional stability

Dimensional stability in a PVC membrane refers to its ability to maintain its original shape and size when subjected to various environmental conditions, such as temperature changes, moisture, and tension. This property is crucial for PVC membranes used in industrial applications, and other construction uses where maintaining the integrity of the material is essential for its functionality and longevity.

Protan BlueSafe®

Protan BlueSafe® is a series of innovative, 100 % recyclable technical textiles that will help, e.g. the farming industry to solve several types of environmental challenges. BlueSafe® meets the aquaculture industry's requirements for sustainability, biosecurity and food safety. BlueSafe® is specifically developed for use in salt water.